Hunhu Zvishandiso Uye Hunhu Kudzora Maitiro

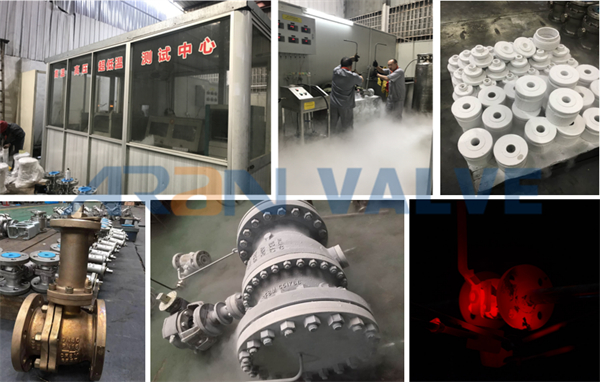

Ese mavharuvhu anoitwa neakanaka emhando yekudzora sisitimu, akavimbika ekuongorora maturusi uye vakanyatsodzidziswa QC vashandi, ARAN inochengeta hunhu sehunonyanya kukosha kune mutengi wedu.

ARAN ine dhipatimendi rekuongorora mukati meimba uyezve yechitatu bato rakatenderwa lab yeakakosha emhando yekudzora, ongororo dzese uye bvunzo dzinoitwa neanokwanisa uye ane ruzivo zvinhu.

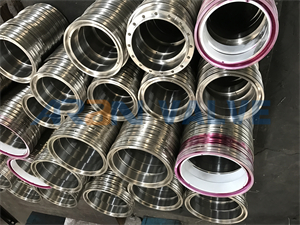

Iyo yemukati yemhando yekudzora midziyo yemidziyo, inova yekukanganisa bvunzo, kuomarara bvunzo, tensile bvunzo, makemikari kuumbwa uye mechaniki zvivakwa lab nezvimwe.

Pakurayira theHunhu Kudzora Chirongwa (QCP) uye Kuongorora uyeInspectionTest Plan (ITP) inogona kupihwa mvumo yeMutengi isati yagadzirwa.

1. Valve mbishi zvinhu kudzora: Visual uye dimension kuongorora, PMI, Wall ukobvu, Impact bvunzo kana nokukumbira, NDE kufanana PT, UT, MT, RT.

2. Valve component machine process inspection: dimension check, machined surface uye zvikamu zvekuongorora zvinhu, chikumbiro chakakosha seNDE bvunzo nechikumbiro chekuraira.

3. Gungano revhavha uye kuongorora kwekushanda: Chikamu chimwe nechimwe chevhavha chiri pasi pe hydraulic uye mhepo yekuongorora kuongorora kwekushanda maererano nekuraira kwechikumbiro, chikumbiro chakakosha sePAT bvunzo nechikumbiro chekuraira.

4. Valve Paint, pasuru uye kuendesa.Chikumbiro chakakosha seyechitatu bato kuongororwa nechikumbiro chekuraira.

General Quality Control Process

Valve raw material control: Visual uye dimension yekuongorora, cheki yezvinhu, PMI, Wall ukobvu, Impact bvunzo kana nekukumbira, NDE.

Valve chikamu chemuchina process yekuongorora: dimension cheki, yakashongedzwa pamusoro uye zvikamu zvezvinhu cheki, yakakosha chikumbiro senge NDE bvunzo nechikumbiro chekuraira.

Kusangana kwevhavha uye kuongorora kwekuita: Chikamu chega chega chevhavha chiri pasi pe hydraulic uye mhepo bvunzo kuongorora kwekuita zvinoenderana nekuraira kwakajairwa chikumbiro.

Valve Paint, pasuru uye kuendesa.

Special Quality Contor Chikumbiro

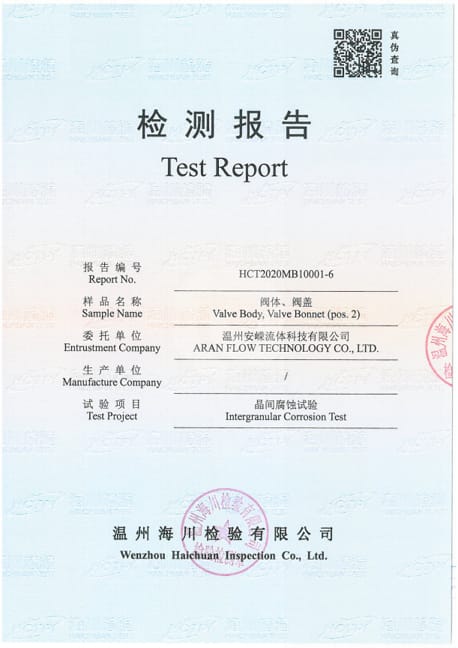

Material test report mu third party lab

- Mechanical uye kukanganisa bvunzo

- Cheki chekuongorora chemakemikari

- Corrosion test

- Ferrite cheki

- Hydrogen inducted cracking test (HIC)

- Sulphide Stress corrosion cracking test

Kusaparadza bvunzo (NDE, NDT)

Kuita kweVT, PMI, UT, PT kunogona kuitwa mumba uye wechitatu kuita UT, PT, MT, RT uye kuoma, uye inosanganisira zvinhu qualification level izvo zvese zvichaitwa acc.kune zvinodiwa nevatengi.

- VT (Visual Test)

- PMI (Positive Material Identification)

- UT (Ultrasonic bvunzo)

- PT (Penetrant test)

- MT (Magnetic particle test)

- RT (X-Ray bvunzo)

- Muedzo wekuoma

Pressure & functional Test

Miyero yekuyedza senge API 598, API 6D, ISO 5208, EN12266-1, GOST 9544 nezvimwe.

- Functional Test / Torque kukosha bvunzo

- Hydraulic bvunzo / Mhepo bvunzo

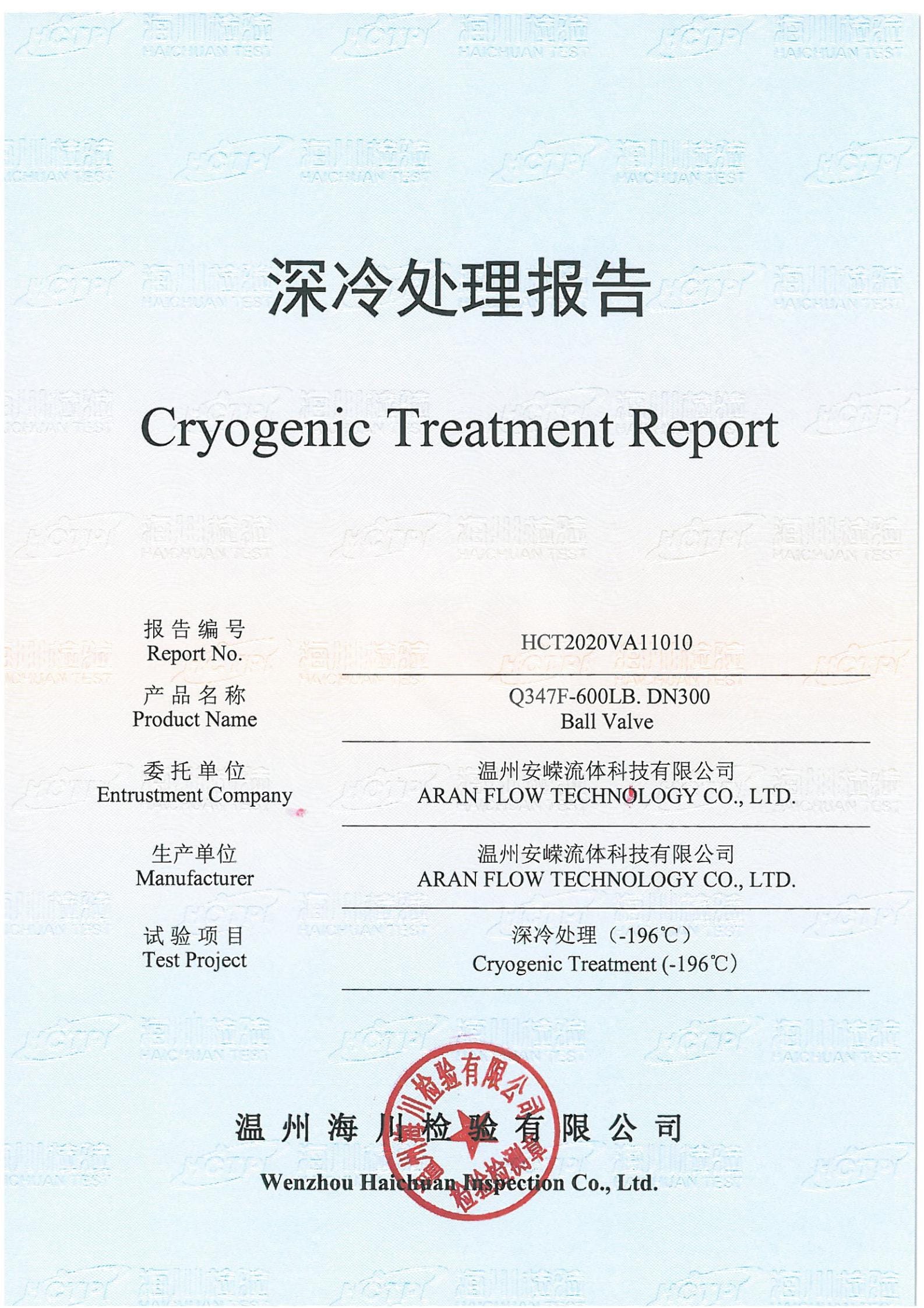

- Kudzikira tembiricha Cryogenic Helium gasi bvunzo -196°C

- High tembiricha bvunzo 600°C

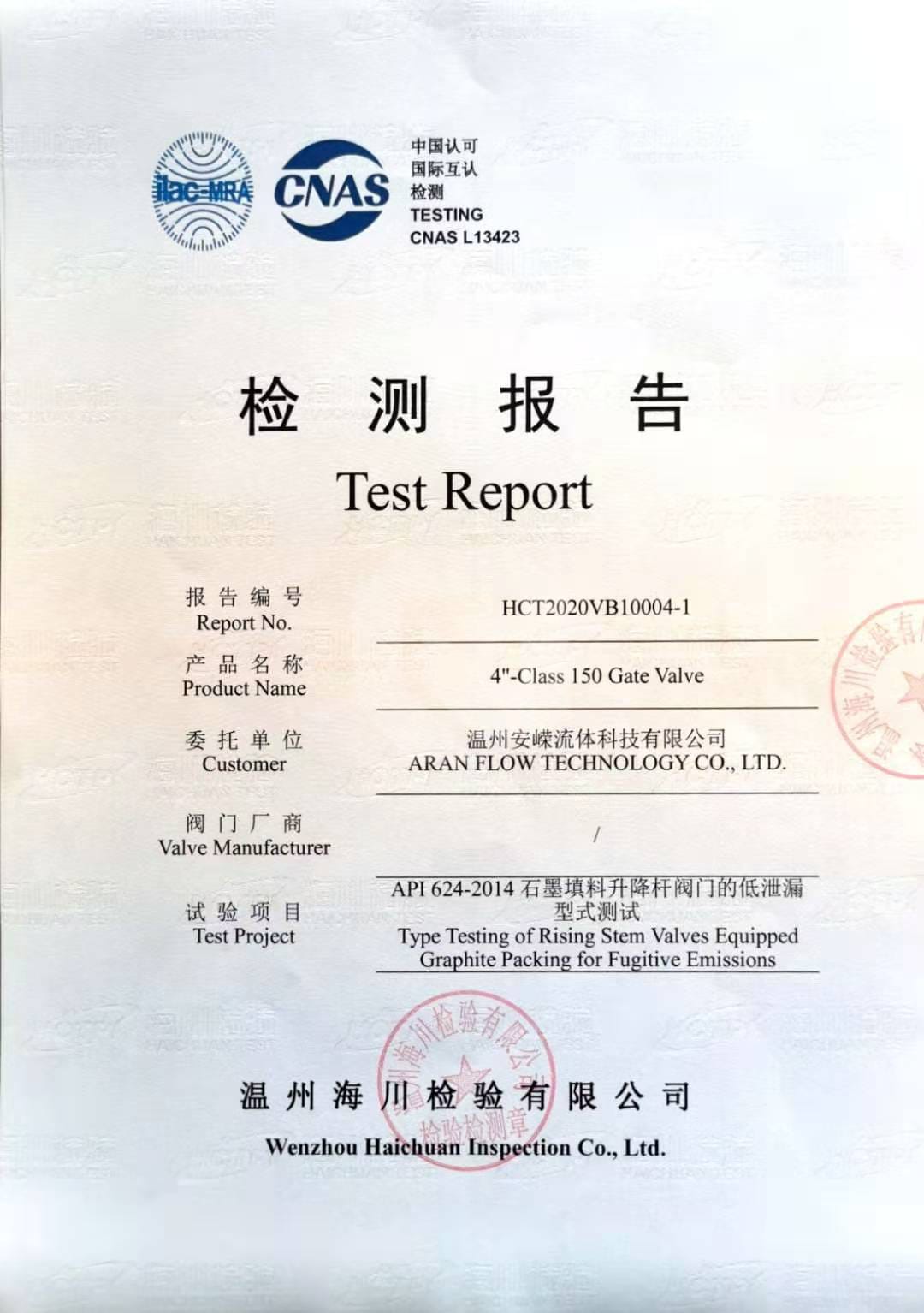

- Fugitive Emission bvunzo 15848-1 kana 15848-2

- Moto-yakachengeteka bvunzo

- FAT bvunzo (yefekitari yekugamuchira bvunzo)

- PAT bvunzo (kugamuchira chigadzirwa bvunzo)

Yakaderera tembiricha Muedzo: iyo yakaderera uye yakakwira tembiricha lab zvivakwa kuita yakaderera kana yakakwirira tembiricha bvunzo zvinoenderana nekuraira zvinodiwa.Muedzo unofumura vharafu kune bvunzo yakaderera tembiricha Cryogenic bvunzo -196 ℃ kana yakakwirira tembiricha -538 ℃